How to Save $2.5 Million On Justice Facility Maintenance

![]() Underfunding corrections and detentions support systems over the past several decades has created a culture of minimum performance that, while necessary to get through tough economic times, is not sustainable from an operations perspective. Now is the time for agencies to create the right maintenance program to realize the long-term return on investment.

Underfunding corrections and detentions support systems over the past several decades has created a culture of minimum performance that, while necessary to get through tough economic times, is not sustainable from an operations perspective. Now is the time for agencies to create the right maintenance program to realize the long-term return on investment.

How’d We Get Here?

“Kicking the can down the road” only leads to increased operational inefficiency and long-term economic loss. Agencies and owners are becoming increasingly aware of the need for strategic approaches to address their maintenance needs. In fact, according to CGL’s Justice Facilities Survey conducted at the American Correctional Association Congress of Corrections, an overwhelming majority of respondents said they are willing to consider alternative approaches to reducing the maintenance they deferred during the economic downturn. In his recent post, “7 reasons for performing a staffing assessment,” Ken McGinnis highlights the fact that the majority of Justice Facilities Survey respondents also considered themselves to be in a staffing crisis.

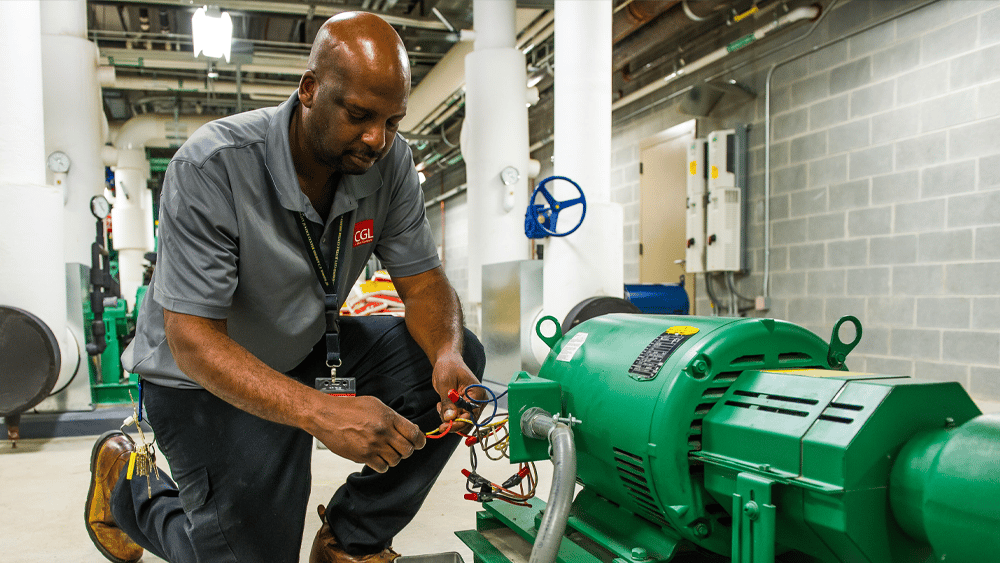

It’s not hard to see the correlation in these results – understaffed facility programs are forced to purposefully defer tasks and forgo measures that are essential to operations. Putting off maintenance leads to early failure of equipment and systems, resulting in inmate management issues, and interfering with the staff’s ability to administer justice.

What’s the Fix?

Renewing properly funded maintenance programs that meet the specific conditions of the facility before systems start to fail is essential to long-term success. Creating maintenance programs that prevent premature aging and failure is the sustainable model; moreover, it has the advantage of costing agencies less over the next 20 years.

According to an independent study performed by Whitestone Research, “Preventative Maintenance Program Comparative Analysis for Criminal Justice Facilities,” providing preventive maintenance, compared to not providing preventive maintenance, saves more than $13 per square foot in maintenance costs over a 10-year period. Savings increase to more than $25 per square foot over 20 years. On average, a 100,000 square foot jail or prison can save $2.5 million per year over 20 years by spending $2.84 per square foot per year ($284,000) for maintenance.

Where Do I Start?

How do you justify the funding to provide the right program for your facilities? Each agency will have different needs. Individual facilities within each system may have unique maintenance requirements. Facility size, type, age, and condition are all factors to consider when establishing the right maintenance service. Facilities with complex equipment systems or outdated building infrastructure will have their own operational challenges. For example, some remote prisons and rural county jails have sewage treatment plants that require very specific personnel, supplies, and materials. Other variables include the magnitude of vandalism, geographic factors (e.g., cold weather or salty air), local labor requirements, availability of personnel, etc.

In any case, the relationship between the facility size and its age provides a starting point for developing an effective budget for a comprehensive maintenance program, focusing on preventive maintenance. Costs are directly related to the size of the facility, while age and condition influence the overall spend necessary to keep the facility functioning as designed:

Recommended Staffing and Spend Rate for Preventive Maintenance in Jail & Prison Facilities

| Facility Size SF | Minimum Recommended Staffing* | Recommended $/SF* | Age Factor Additional $/SF | ||

|---|---|---|---|---|---|

| <10 years | 15-20 years | >20 years | |||

| 100,000 | 3-5 | 3.00 | .15 | 50 | .75 |

| 250,000 | 7-9 | 2.75 | .15 | .50 | .75 |

| 500,000 | 15-17 | 2.65 | .12 | .40 | .60 |

| 1,000,000 | 30-35 | 2.50 | .10 | .40 | .60 |

* Includes all necessary trades, management, and administration

** Includes all relevant costs, including labor, supplies, subcontractors, etc.

Providing your budgeting authority with justification for your maintenance program begins with measuring your program and identifying the right spend rate for your individual facility needs. Your spend rate can be boiled down to a dollar-per-square-foot calculation, but is made up of variable costs, such as:

- Non-skilled labor

- Skilled labor, with variance between disciplines such as plumbing, electrical, HVAC, etc.

- Availability of inmate labor

- Specialty subcontractors and certifications

- Employee benefits

- Materials and supplies

- Replacement and renovations, including project management

- Capital improvements, including project management

- Administration

- Licensing, permitting, or other regulatory costs

- Certification requirements

If the thought of tracking these costs seems overwhelming, it shouldn’t. Thanks to modern technology, tools like CMMS systems can shoulder the burden of collecting this information and take the guess work out of the equation.

Once identified, the necessary resources for your facility and the cost per resource can be applied to the building area. The resulting costs can be presented as a budget line item that can be compared to long-term maintenance costs and overall facility value, solidly justifying the spend year-to-year.

How do we know?

Gregory Westbrook has more than 24 years of dynamic and diverse facilities operations experience and comes from both operations and instruction backgrounds, relating to complex engineering environments, enhanced building performance, increased productivity, and cost efficiencies.

Ready to clear the backlog and get your maintenance program back on track? Let’s talk: gwestbrook@cglcompanies.com; (678) 381-6583