From Potential to Practice: How AI-Powered Facility Condition Assessments Are Transforming FM Challenges into Solutions

ABOUT TODAY’S POST:

Artificial intelligence is no longer a future concept for facility managers — it’s rapidly becoming an everyday tool reshaping how we assess, manage, and maintain public facilities. In this blog, Billy Holder, former CGL employee and now CEO and Founder of ProjectAidra, shares how AI is revolutionizing Facility Conditions Assessments (FCAs) and solving real-world challenges for facility managers. With nearly three decades of experience spanning hands-on construction to executive leadership, Billy has combined his expertise in facility maintenance, management, and cutting-edge technology to develop solutions that reduce administrative burden, improve data quality, and return focus to strategic decision-making. This post builds on Billy’s first article, Making Your Resources Go Further – How to Utilize AI in Facility Management, by taking the conversation a step further—diving deeper into the role of AI in Facility Conditions Assessments and the practical, measurable impact it’s already delivering. This post explores how AI is being applied today to streamline condition assessments, automate asset capture, meet new compliance standards, and deliver tangible ROI for organizations managing complex facilities.

The conversation has shifted. Six months ago, facility managers were asking “Will AI help our operations?” Today, they’re asking “How do I implement AI in my workflow?” The difference isn’t just semantic — it represents a fundamental shift from theoretical potential to practical application. As someone who’s spent 28 years in this industry, from swinging hammers to managing portfolios, I’ve watched facility management evolve through countless technology waves. But AI feels different. It’s not just another software platform we need to learn — it’s a tool that actually understands our work and makes it easier.

The built environment spends an estimated $17 billion annually on inspection labor alone[1]. That’s a staggering number that represents countless hours of facility managers walking buildings with clipboards and legal pads. But what if we could reclaim 85% of that administrative burden while improving the quality of our data and providing better strategic value to the organizations we are a part of?

Facility Conditions Assessments: From Days to Hours

Let’s start with the reality most of us face: comprehensive Facility Conditions Assessments are critical but time-consuming. A traditional Facility Conditions Assessment for a 50,000-square-foot building can easily consume 2-3 days of fieldwork, followed by another week or more of report compilation. AI is changing this equation by handling the documentation burden, freeing subject matter experts to apply their knowledge where it’s really needed — not writing down serial numbers.

Real-world results: A facilities consultant recently used AI for asset collection of a 75,000-square-foot facility containing over 50 assets, from electrical panels to 40+ year-old air handlers. What would have typically taken three days to collect by hand was completed in four hours of walkthrough time. This freed him to spend quality time inspecting structure, functionality, and engaging with the client. The time savings didn’t stop there: by the time he finished day one, the complete asset report was ready for download as a CSV file, eliminating another three days of post-visit administrative documentation. The transformation isn’t just about speed — it’s about returning expertise to where it matters most. Instead of having skilled professionals transcribe model numbers, they can focus on evaluating conditions, identifying risks, and making strategic recommendations.

Asset Capture: Solving the Inventory Puzzle

Every facility manager knows the frustration: you need to order a replacement part, but first you need to find the model number, manufacturer, and specifications. Cue the inevitable trip to the mechanical room with a flashlight and a prayer that the nameplate is still readable. AI-powered asset capture modules are changing this dynamic entirely. These systems can read equipment nameplates, identify manufacturers, and automatically populate asset databases, even from video captured during routine walkthroughs. This drastically improves the quality of data and reduces the amount of time spent collecting the information.

The practical impact: Instead of spending hours manually cataloging equipment, facility managers are building comprehensive asset inventories as a byproduct of their regular inspections. One facility manager shared that they discovered equipment they didn’t even know existed in their building — equipment that was due for maintenance and could have failed without warning. This isn’t just about efficiency; it’s about risk management. When you know exactly what equipment you have, where it is, and what condition it’s in, you can make proactive decisions instead of reactive ones.

Thermal Imaging: Meeting NFPA 70B Requirements with AI

The 2023 update to NFPA 70B transformed electrical maintenance from recommended practices to mandatory standards. For facility managers, this means developing comprehensive Electrical Preventive Maintenance (EPM) programs that can prevent failures and ensure safety — and thermal imaging is a critical component of that compliance. Traditionally, meeting NFPA 70B thermal imaging requirements meant hiring specialized contractors with expensive equipment. Technology is changing this by making thermal analysis accessible through standard smartphone attachments and AI automated interpretation that can identify electrical hot spots, overloaded circuits, and failing connections.

Real-world scenario: A facility manager conducting routine electrical panel inspections uses AI-powered thermal analysis to identify temperature anomalies that indicate loose connections — potential failure points that could have led to equipment damage or safety hazards. The AI automatically documents the findings and prioritizes repairs based on risk level.

The result: Proactive maintenance instead of reactive repairs, full compliance documentation, and significant cost savings compared to traditional thermal imaging services.

Integration: Working With Your Existing Systems

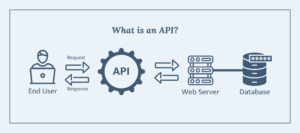

Here’s where the rubber meets the road: any new technology needs to work with your existing workflows, not replace them entirely. This is where APIs (Application Programming Interfaces) become crucial—they’re the digital bridges that allow different software systems to communicate. You should think of APIs like universal translators for software. Your CMMS speaks one language, your accounting system speaks another, and your new AI assessment tool speaks a third. APIs allow them all to share information seamlessly.

The AI industry is rapidly evolving how these integrations work. Instead of rigid, pre-programmed connections, we’re seeing more intelligent APIs that can adapt to different data formats and workflows. This means AI tools can integrate with your existing CMMS, automatically creating work orders from identified issues, updating asset records, and even triggering preventive maintenance schedules.

Practical example: When an AI assessment identifies an equipment asset, it can automatically enter it into your CMMS, attach the relevant photos, include manufacturer specifications from the asset database, and even provide cost estimates for the replacement. All without manual data entry. Sounds like something out of Star Trek, right? Well, it’s not the future- it’s already here!

The ROI Reality Check

Let’s talk numbers because that’s often what matters to leadership. The administrative aspect of traditional assessments — documentation, data entry, report compilation — represents a significant cost that many organizations haven’t fully quantified. AI-powered assessment tools can reduce this administrative workload by up to 85%. But what does that mean in real dollars for your operation? The variables include your current assessment frequency, team size, and time spent inspecting, but the calculator we’ve developed can help you model the potential impact for your specific situation. Check out this ROI calculator to see how these time savings translate to your bottom line.

Moving From Potential to Practice

The facility management industry has often found itself behind the technology curve — not by choice, but because most solutions weren’t built by people who understand the daily challenges. AI is different because it’s finally sophisticated enough to handle the complexity and variability of facility management work. The key to successful implementation isn’t about replacing your expertise — it’s about augmenting it. AI handles the repetitive, time-consuming documentation tasks so you can focus on analysis, strategy, and the human elements that technology can’t replace. Getting started doesn’t require a complete workflow overhaul. Begin with a single building or a specific type of assessment. Test the technology, understand its capabilities and limitations, and gradually expand its use as you build confidence and see results.

Your Path Forward

The facility management landscape is evolving, and every organization has unique needs and constraints. You have three clear options:

Status Quo: Continue with current manual processes while administrative burden and labor costs keep climbing. Sometimes maintaining existing workflows is the right choice, but the gap between leaders and followers is widening.

Partial Solutions: Experiment with basic digitization or limited AI tools. You’ll see some improvement, but fragmented approaches often create new challenges while solving only part of the problem.

Strategic Partnership: Work with a solution built by industry insiders who understand that no two facilities are alike. Whether you’re managing corporate campuses, educational institutions, healthcare facilities, or specialized environments, the right AI partner adapts to your needs — not the other way around. The most successful implementations happen when technology providers truly understand your daily challenges and can customize solutions that work within your operational reality.

Source:

- Calculated based on data from the International Facility Manager Association.